By Anja Chalmin

Since 2017, the companies Carbfix and Climeworks have been working on joint projects to capture CO2 and inject it underground in Iceland. Now this cooperation is to be expanded further: Climeworks aims to multiply the amount of CO2 captured and Carbfix aims to increase the scale of underground injections. This also implies an intensification of the project’s already high energy and water demands. For example, the energy consumption of Climeworks’ DAC technology remains high and increases linearly with the amount of CO2 captured. In the case of subsurface injection of CO2, it remains unclear whether all the risks and impacts, which can become critical especially in a large-scale implementation scenario, have been fully understood.

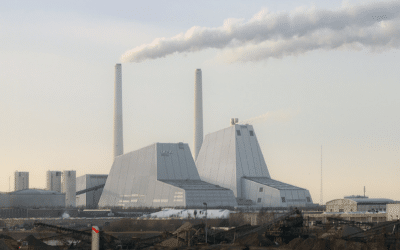

The company Carbfix, since 2019 established as a subsidiary of Reykjavik Energy, was initiated as a project in 2006 and formalised in 2007 by four founding partners: Reykjavík Energy, the University of Iceland, the CNRS in Toulouse and the Earth Institute at Columbia University. Carbfix is located at the Icelandic geothermal power plant Hellisheidi (Hellisheidarvirkjun), in the Hengill geothermal area, about 25 km east of Reykjavík. The heat and power plant was commissioned in 2006 and is owned and operated by ON Power, another subsidiary of Reykjavík Energy. Iceland’s largest geothermal power station has a capacity of 200 megawatts in thermal power and 303 megawatts in electricity. It supplies hot water and electricity to Reykjavik city and emits about 40,000 tonnes of CO2 per year.

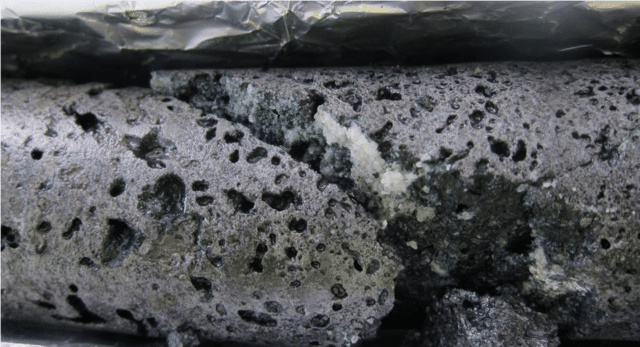

From 2011 to 2021 – after almost five years of modelling and lab-scale R&D – the pan-European research projects CarbFix and CarbFix2, led by Reykjavík Energy, were funded with € 3.77 million under the European Research Framework Programmes 7 and 8. The projects advanced the process developed by Carbfix. In this process, carbon dioxide (CO2) and hydrogen sulphide (H2S) are first dissolved in water through a water scrubbing process – a physical process in which the gases are brought into contact with water under pressure. Then the dissolved gases are injected into basaltic formations at 400 to 800 m depth, with the objective of storing the gases in mineral form in the bedrock. The injections into basaltic formations started in 2012, three kilometers southwest of the Hellisheidi plant. With this approach, the project captures and injects 33 % of the Hellisheidi plant’s CO2 emissions and 75 % of the H2S emissions. Carbfix says that the dissolved CO2 is mineralised in porous basaltic rock. So-called carbonates are formed through contact with minerals such as magnesium, calcium and iron. According to Carbfix 95 % of the dissolved CO2 turns to carbonates in about two years, the dissolved H2S within four months.

The Swiss company Climeworks AG joined CarbFix2 in 2017 and provided a Direct Air Capture (DAC) module with a capture capacity of up to 50 tonnes of CO2 per year. The DAC module captures CO2 from ambient air, using a chemical filter. For this, ambient air is blown through the module with large fans. Once the filter is saturated, the CO2 can be released and isolated – by sealing the module, raising the temperature (80-100°C) and creating pressure (vacuum). One run takes about four hours and the process needs ~2,000 kWh of thermal energy and ~650 kWh of electricity to capture one tonne of CO2. The CO2 thus separated from ambient air is also mixed with water and injected, at a depth of 1,000 metres, into nearby underground basaltic layers for mineralisation. In September 2021, the CO2 capture capacity was scaled to up to 4,000 tonnes per year with the commissioning of Climeworks’ Orca facility, in close proximity to the Hellisheidi plant. The facility consists of eight containers, each with an annual CO2 capture capacity of up to 500 tonnes.

The Climeworks AG estimated the cost of building Orca, including development and storage, to be in the range of 10 to 15 million USD. Where exactly the funds for the project came from is not known, but more than € 150 million in public and private grants for Climeworks are known to the public so far. The 2020 funding round alone raised more than € 90 million and in 2021, Swiss Re and Climeworks signed an agreement worth US$ 10 million. Since June 2019, 8,000 private customers have signed up for the purchase of carbon offsets, at the CarbFix project site, at a price of US$ 1,200 per tonne of CO2. If bought in bulk, the price per tonne of CO2 is close to US$ 600. Microsoft pre-purchased 1,400 tonnes of CO2 removal from Orca for an undisclosed amount, and Shopify pre-purchased 5,000 tonnes. These payments helped Climeworks to move forward with the planning and constructions of Orca. Prices of US$ 600 to US$ 1,200 per tonne of CO2 are high and an impairment to the growth of the DAC industry. Although Orca has multiplied the DAC capacity compared to previous Climeworks installations, the cost per tonne of CO2 captured has remained almost unchanged at a high level. According to Climeworks, „far from the levels around $100 to $150 per ton that are necessary to turn a profit without the help of any government subsidies”. The oil and gas company Shell has indicated “direct greenhouse gas emissions” of 63 million tonnes of CO2 equivalent for 2020. At a price of US$ 600 per tonne, this would mean a cost of US$ 37.8 billions.

The persistently high costs are one reason why Climeworks is far from its original target of capturing 1 % of annual global CO₂ emissions by 2025, more than 300 million tonnes. This year, Climeworks revised the target downwards to 0.5 million tonnes by the end of the decade. By comparison, according to the International Energy Agency, the global energy-related CO2 emissions in 2020 amounted to 31.5 gigatonnes of CO2. Orca’s current capacity, 4,000 tonnes of CO2, is equivalent to the average annual CO2 emissions from 2,425 new passenger cars in the European Union[i]. Not only the costs, but also the energy input per tonne of CO2 captured has remained high at Orca, even when compared to previous Climeworks plants. To capture 4,000 tonnes of CO2 annually, the Climeworks capture process requires ~8 million kWh of thermal energy and ~2.6 million kWh of electricity. This means that by operating Orca, the Hellisheidi plant has ~10.6 million kWh less available annually to supply customers in Reykjavik. In 2017, Icelandic households had an average annual energy consumption of 77 MJ/capita, meaning Orca’s annual energy demand would supply more than 495,500 inhabitants – which is more than the average annual energy consumption at household level of all inhabitants of Iceland (population: 361,000).

Both companies, Carbfix and Climeworks, intend to further expand their CO2 capture activities in Hellisheidi. Following the commissioning of Orca, Climeworks is already considering to expand the DAC capacity at Hellisheidi tenfold in about three years. With today’s technology, this would result in a tenfold increase in energy consumption.

In August 2021, Carbfix and ON Power, now both subsidiaries of Reykjavík Energy, received a € 3.9 million grant from the European Union Innovation Fund for the Silverstone project. Silverstone plans to commission a new CO2 capture plant by 2025, aiming to capture and store 34,000 tonnes of CO2, equivalent to 85 % of Hellisheidi’s CO2 emissions. Carbfix has also plans to expand its CO2 capture and injection activities at ON Power’s Nesjavellier geothermal power plant, located north of Hengill area, with a capacity of 300 megawatts in thermal power and 120 megawatts in electricity.

In addition, a CO2 transport and mineral storage hub – the Coda Terminal – is to be built in Straumsvík Bay, southwest of Reykjavik. CO2 captured through DAC in Iceland, as well as ships with cooled CO2 from industrial sites in Northern Europe are to arrive there and the CO2 is to be injected into basaltic formations near Straumsvík using the Carbfix method. In October 2021, Carbfix signed a Memorandum of Understanding with the Straumsvík-based aluminum manufacturer Rio Tinto, which allows Carbfix to use the land surrounding the smelter for onshore CO2 injections. The Danish shipping company Dan-Unity CO2 has signed an agreement with Carbfix for the transport of CO2 to the Coda Terminal. Carbfix aims to start the Coda Terminal operations in 2025, with 0.3 million tonnes of CO2 per year. From 2030, at full scale, the project plans to inject 3 million tonnes of CO2 per year. The investment for the project is estimated at € 220-250 million. Annual revenues are estimated at around € 25-45 million at full capacity. According to Carbfix, there is enormous potential for the application of the Carbfix technology in the global geothermal sector. Carbfix also sees application possibilities in silicic rocks at sites in the USA, Mexico, Nicaragua, El Salvador, Costa Rica, Italy, Japan, the Philippines, New Zealand, Indonesia and Kenya. Further development of the Carbfix method at other sites is already underway with the GECO project. Since 2018, the Hellisheidi power plant has also been home to the pan-European research programme “GECO – Geothermal Emission Gas Control“, which is funded by the European Union with € 15.6 million and also coordinated by Reykjavík Energy. GECO builds upon the CarbFix-projects and aims, inter alia, to reduce the consumption of resources – water, chemicals and energy, lower the cost of the captured CO2, increase the purity of the captured CO2 and improve public acceptance of the Carbfix concept. GECO also established four additional demonstration sites, each with a distinct geology: Iceland’s second largest geothermal power station Nesjavellir, the Italian geothermal site Castelnuovo, the Kizildere geothermal field in Turkey, and the German geothermal underground test site TRUDI.

Carbfix’ calculation of the carbon footprint of the Coda operation appears to be incomplete. The energy input for the CO2-capture process, the liquification of the captured CO2 for transport and all means of transportation (shipping, and land transportation to the port) need to be fully taken into account. As with Climeworks’ DAC technology, large-scale implementation may lead to the consumption of large amounts of energy that would have to come from renewables – which are urgently needed elsewhere. The enormous energy demand of these technologies could therefore lead to higher fossil fuel consumption in the near future and prolong dependence on the fossil fuel industry.

Furthermore, Carbfix does not provide precise details on the water consumption of its method, but states that “The Carbfix process requires substantial amounts of water to carry the CO2 in dissolution and to promote reactions underground”. One source says that the Carbfix process requires 25 tons of water for one ton of CO2. This means that a large-scale introduction of the Carbfix technology could exacerbate demand not only for energy, but also for water. In order to be able to use the Carbfix process in regions where water is scarce, Carbfix is planning first trials with seawater in late 2021 and further trials in 2022. It remains unclear in the project descriptions to what extent the risk of saline water rising back up into the groundwater zone after large-scale use and affecting drinking water, biotopes or agricultural land will be taken into account.

Though this technology is advancing rapidly, questions remain about whether all the risks and impacts that can occur during large-scale implementation have been fully explored. For example, a seismic study in Hellisheidi observed surface displacements of up to 2 cm during the initial phase of injections in Hellisheidi from 2011-2012 and attributed these to the fluid injections. Extending transport routes is also associated with greater risk, e.g., leaks in CO2 pipelines. Another study reports that basaltic rocks are recognized as one of the most important habitats on Earth because they harbour a diverse and active microbial population. The study criticises that this living component is rarely considered in CO2 injection projects. The study reports, that acidic groundwater enriched with CO2 can lead to a significant decrease in microbial diversity and can promote the growth of autotrophic and heterotrophic microorganisms, whose activities can have an impact on mineral storage and inhibit conversion of CO2 into carbonates. With the huge energy demands of Climeworks, unresolved risks and intensive use of water, investment in this project is a dangerous distraction from initiatives that actually reduce carbon emissions.

[i] EU average annual distance travelled by car: 12,000 km; average CO2 emissions from new passenger cars: 122.3 g of CO2 per kilometer in 2019