By Anja Chalmin

Introduction

In March 2022, the European Commission announced that it is spending € 1.1 billion co-funding seven large-scale climate projects. Among them are five geoengineering projects, which will cost € 880 million, adding up to 80 % of the total investment. Four of these geoengineering projects aim to capture CO2 and inject it under the seabed of the North Sea. Thus far, the European Union’s demonstration projects, which were conducted over the last decade to study the feasibility and economic viability of carbon capture and storage (CCS) have all failed due to financial and/or technical hurdles. On this basis, it is uncertain how the European Union will ensure that the North Sea, which is criss-crossed by more than 20,000 drilling wells, will be a safe long-term storage site for captured CO2, especially with the potential risk of tectonic movements.

Carbon capture and storage geoengineering projects are being funded also at the national level in Europe, including BECCS projects in the UK and Sweden. Private sector carbon markets and carbon removal standards set up by companies to sell voluntary carbon removals also encourage the emergence or expansion of greenhouse gas removal (GGR) projects, including biomass-based or direct air capture (DAC) projects. The European Union (EU) is seeking to create an EU-wide common carbon removal standard for these markets in order to harmonise the public and private carbon removal certification schemes currently in place and “to ensure that the same rules and methodologies for the certification of carbon removals are applied across the EU“.

Certification of carbon removal in the European Union

In June 2021, with the adoption of the European Climate Change Act, Reg. (EU) No. 2021/1119, the European Union committed to removing as many greenhouse gases as it emits by 2050 at the latest, and achieving so-called negative emissions thereafter. In October 2021, the European Commission had announced that it would develop a proposal for the certification of carbon removal, to bring carbon reduction-based business models for land managers and industrial companies in line with the objectives of the European Green Deal and European climate law. The measure aims to facilitate capturing CO2 from the atmosphere and “durably storing it in terrestrial and marine ecosystems, geological reservoirs or products without damaging ecosystems. By 2050, both natural ecosystems and industrial solutions should contribute to removing several hundred million tonnes of CO2 per year from the atmosphere.” An EU-wide common standard for carbon removals intends to harmonise the public and private carbon removal certification schemes currently in place and “to ensure that the same rules and methodologies for the certification of carbon removals are applied across the EU”. Moreover, it should be achieved that by 2028,

- “every land manager should have access to verified emission and removal data, and carbon farming should support the achievement of the proposed 2030 net removal target of 310 Mt CO2eq in the land sector”;

- “any ton of CO2 captured, transported, used and stored by industries should be reported and accounted from its origin; by 2030, at least 20 % of the carbon used in products should come from sustainable non-fossil sources; and by 2030 5Mt of CO2 should be annually removed from the atmosphere and permanently stored through technological solutions”.

The number of net-zero pledges (the essence of Net Zero is that a company removes as much greenhouse gas or buys as many carbon credits as it emits) by companies, but also by regions and cities in Europe is steadily increasing. Several companies have responded to the demand for carbon removal, including Puro.earth, a carbon removal marketplace founded in Finland in 2018. Puro.earth was among the first companies to develop a standard for voluntary carbon removals and market carbon removals on this basis and sell carbon removal certificates to companies that voluntarily work towards net zero emissions. More than 40 % of sales involved biochar projects.

In April 2022, biochar producer Glanris announced that a life cycle analysis (LCA) had been carried out for its biochar on behalf of Puro.Earth and that it was now classified as net CO2 negative. The scope of the LCA “covered the harvesting, transport and handling of sourced rice hulls and Glanris’ manufacturing emissions”. It was also stated that “the results show that each tonne of biochar sequesters approximately 1 tonne of CO2 for 100 or more years, even after production and transport emissions are accounted for.” These statements raise questions, for example why an LCA for an agricultural product only starts at the time of harvest. Until harvesting, the rice field is processed several times with fuel-intensive agricultural machinery, starting with soil preparation before sowing. All fertiliser and crop protection measures must also not be disregarded in an LCA, as the production of these off-farm inputs is also energy-intensive. The basis for the statement that CO2 is sequestered for a hundred years or more is particularly questionable, since there are very different results on the stability of biochar in soils and long-term studies are lacking. Moreover, even the stated hundred years is not a durable storage solution.

Future investments in biomass-based carbon removal in the European Union

Worldwide, many new biochar projects are currently being developed, and the same goes for Europe and the UK, including the Reverse Coal Project at Pollybell Farms near Doncaster, UK. The project is being carried out by Lapwing Energy Ltd in collaboration with the University of Lincoln, the UK Centre for Ecology and Hydrology, the University of Exeter and SLR Consulting. The project aims to grow short rotation willow, produce biochar from willow chips and permanently sequester five million tonnes of CO2 over the projects lifetime. While it is unclear how this amount of CO2 was calculated, it is clear that each of the production steps described in the project – the cultivation of the willow including tillage, the harvesting of the willow, the transport of the harvested material, the shredding of the willow into woodchips, the drying of the woodchips and the pyrolysis itself – is very energy-intensive and a potential source of greenhouse gas emissions. Another product of the pyrolysis process is the pyrolysis gas, which is to be burnt to dry the willow woodchips. The combustion of the gas releases climate-relevant emissions. In addition, the gas must first be cooled, cleaned and dehumidified with energy consumption before it can be burned. Whether so-called negative emissions can be generated in this manner is questionable.

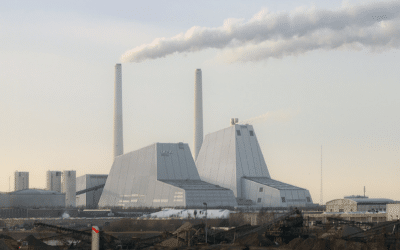

Another biomass-based project in the UK that aims to capture CO2 on a large scale is the Drax Power Station near Selby in North Yorkshire, the UK’s largest power station, which generates six percent of the UK’s electricity. Over the past ten years, Drax has converted four of its six units from coal to wood pellets, with the goal of achieving a “negative carbon footprint”. In late 2021, Drax announced a £ 40 million investment to drive the development of its BECCS project. By 2030, Drax plans to process eight million tonnes of pellets annually. From 2027, the company aims to capture CO2 emissions at its Selby plant and capture eight million tonnes of CO2 per year by 2030.

Most of the wood pellets used are imported from North America, more than 80 %. Drax now owns 17 biomass pellet plants in North America. For pellet production, trees are harvested, crushed, dried, pelletised, packaged and transported regionally and internationally in energy-intensive processes. Each of these energy-intensive steps is a potential source of greenhouse gases. It seems unlikely that a LCA that takes into account all the steps and the international transport routes, as well as the energy-intensive CO2 capture process and further handling of the captured CO2, would conclude that this project has a negative carbon footprint. Moreover, it should not be forgotten that deforestation and burning of wood means that a climate-protecting carbon reservoir releases all the carbon it contains in an instant and increases the level of CO2 in the atmosphere. According to the European Academies’ Scientific Advisory Council (EASAC), it takes between 50 and 100 years for the amount of CO2 released from burning wood to be recaptured by regrowing forests.

Two more BECCS projects have started in the UK in the past year. Both are funded by the UK government’s Direct Air Capture (DAC) and Greenhouse Gas Removal (GGR) innovation programme. InBECCS has been conducting a feasibility study since 2021 for a BECCS project in the north-west of England, to be connected to the existing 28.5 MW biomass gasification plant ‘Ince Bio Power Facility’ in Protos, Cheshire. A feasibility study has also been underway since 2021 as part of the KEW Technology project. The project approach combines CO2 capture and hydrogen production and is to be tested at the KEW Technology gasification plant in Wednesbury near Birmingham, UK.

In 2021, new BECCS activities were also announced in Sweden. Biorecro, a Swedish company developing BECCS technology, announced SEK one million in funding from the Swedish Innovation Agency to develop a future BECCS facility at Söderenergis’ Igelsta plant. The funding will also be used to develop a method for potential BECCS producers to prove that their process produces negative emissions. This method will then be tested at the planned future BECCS plant at Söderenergis Igelsta. Igelsta is Sweden’s second largest biomass-fired combined power and heating plant, consuming 17,000 tonnes of fuel per week at full capacity (0.88 million tonnes of fuel per year). The project is being carried out by Biorecro, the Research Institute of Sweden, Söderenergi and KLIMPO.

The European Union Innovation Fund invests in large-scale CCS proposals

As mentioned in the introduction, the European Commission announced seven projects selected for funding under the first Innovation Fund call for large-scale projects in March 2022. The European Union Innovation Fund intends to advance “breakthrough technologies for renewable energy, energy-intensive industries, energy storage, and carbon capture, use and storage”. The European Union expects to spend around € 25 billion on the program in the period 2020-2030, financed by the European Emissions Trading Scheme (ETS), based on a carbon price of € 50 per tonne of CO2. The first call for large-scale projects was launched in 2020 and 311 applications were received. In 2021, the 70 best-ranked projects were invited to submit a full project proposal. The seven large-scale projects in the final selection include five geoengineering projects, supported by the Innovation Fund with a total of € 880 million, to be implemented in Belgium, Finland, France, Spain and Sweden, including one BECCS (Bioenergy with Carbon Capture & Storage) project, one CCUS (Carbon Capture Use & Storage) project and three CCS (Carbon Capture & Storage) projects. Of the remaining two projects, supported with a total of € 260 million, the TANGO project plans to develop innovative, high-performance photovoltaic modules and HYBRIT aims to replace fossil fuels with renewable energies in the steel sector.

The BECCS project selected for funding, BECCS Stockholm Project, is funded by the European Union with € 180 million, is led by the Swedish heating and energy utility Stockholm Exergi Holding AB and aims to deliver the first large-scale commercial BECCS plant in Europe. The planned BECCS facility will be attached at an already existing heat and power biomass plant in Stockholm. At this plant, Stockholm Exergi has already been operating a small-scale R&D facility since the end of 2019 to gain practical experience with BECCS before designing a larger-scale plant. The large-scale BECCS plant is scheduled to go into operation at the end of 2026. The captured CO2 will be liquefied and transported by ship to the North Sea to be injected below the seabed. Stockholm Exergi plans to outsource this part of the project and cooperate with the Norwegian Northern Lights Project, for example. In 2019, Stockholm Exergi and the Northern Lights Project have already signed a preliminary memorandum of understanding for the handling of the CO2. Stockholm Exergi is a member of the Negative Emissions Platform, a Brussels-registered lobbying organisation that aims to raise awareness of geoengineering approaches among policymakers and the general public, and to advocate for public funding for so-called ‘negative emissions’.

The ECOPLANTA project is a CCUS project being planned at the petrochemical complex in El Morell, near the port of Tarragona in Spain. The project is funded by the European Union Innovation Fund with € 106 million, coordinated by Ecoplanta Molecular Recycling Solutions S.L. and conducted in collaboration with SUEZ Recycling & Recovery Spain, Repsol, and the Canadian company Enerkem. The project partners aim to deliver a waste-to-fuel plant to produce 0.2 million tonnes of methanol per year from non-recyclable municipal waste, thus reducing waste that would otherwise end up in landfills. The waste-to-fuel plant is expected to be able to process poor quality, mixed and contaminated waste streams. The CO2 produced will be captured and used as feedstock for the production of chemical products such as methanol. According to Ecoplanta, potential customers for the chemical products are located in the immediate vicinity of the planned plant. The production of synthetic feedstocks such as methanol requires several very energy-intensive steps. There is no indication yet how the required energy will be generated and whether CO2 will be released in the process. However, the CO2 utilized to produce methanol is re-emitted into the atmosphere as soon as the methanol is consumed.

The K6 Program is a CCS project supported by the European Union Innovation Fund with € 153 million. The project is coordinated by Eqiom and targets CO2 capture at Eqiom’s cement plant in Lumbres, northern France. The K6 Program envisages the use of Air Liquide’s CO2 capture technology CryocapTM. From 2028, the CO2 emitted by the cement plant is to be captured, liquefied and injected under the North Sea. For this, it must first be transported as far as the port of Dunkirk, 50 km away. For the underground injection of the captured CO2, the project intends to cooperate with partners such as the Northern Lights Project. Steps such as the capture, liquefaction and transport of CO2 are energy-intensive and it is still unknown whether these steps will rely on energy sources that emit CO2.

The Sustainable Hydrogen and Recovery of Carbon (SHARC) project is coordinated by Neste Oyj and located at Neste’s Porvoo refinery in Kulloo, Finland. The project is supported by the European Union with € 88 million and plans the transition from the production of grey hydrogen (based on fossil-fuels) to the production of green hydrogen (electrolysis, based on renewable energy) and blue hydrogen (combining natural gas & CCS). Whether grey hydrogen will be completely replaced is not yet known, nor is the planned proportion of green hydrogen. The renewable energy for the production of green hydrogen is to be obtained from wind. From 2025, the CO2 captured during the production of blue hydrogen is to be liquefied, transported to the North Sea and to be injected under the seabed.

The Kairos@C project is located in the port of Antwerp, Europe’s second largest port, is coordinated by Air Liquide Large Industry SA and implemented in collaboration with BASF Antwerp NV. The project is funded by the European Union Innovation Fund with € 357 million to bring a large-scale CCS project for CO2 capture, liquefaction, shipping and subsurface disposal (below the seabed in the North Sea) into operation from 2025. The CO2 is to be captured at five different industrial plants in the port of Antwerp, including an ammonia plant, two ethylene oxide plants and two hydrogen plants. The CryocapTM Technology developed by Air Liquide will be used to capture the CO2 at the industrial plants.

Air Liquide is involved in two of the five geoengineering projects funded and has also previously participated in European Union-funded research projects on CCS, including the ENCAP (Enhanced Capture of CO2) project. The aim of the ENCAP project was to develop new CO2 capture technologies for power generation from fossil fuels. The project concluded that ”the technology lacks technical maturity and is far from being implemented in large power plants”.

Air Liquide has also already been involved in several CCS initiatives, most of which were cancelled for cost reasons. For the Green Hydrogen CCS project, planned in the Netherlands, Air Liquide had applied for public funding, but the support was not granted. The CCS project France Nord, which was to be implemented in the north of France similar to the K6 Program, was cancelled because no suitable CO2 storage site could be found. Air Liquide was also involved in CCS projects in North America, both projects, South Swan Hills and FutureGen, were discontinued for financial reasons in the absence of public funding.

Four of the large-scale geoengineering projects selected and supported by the Innovation Fund intend to inject captured CO2 under the North Sea for “long-term storage”. On what scientific basis the European Union or the companies involved can ensure that the CO2 injected underground will be permanently stored is not clear. Is the European Union relying too much on the statements of the numerous lobby organisations in Brussels, including the Coalition for Negative Emissions, Eurogas, GasNaturally, Hydrogen Council, Negative Emissions Platform, Zero Emission Platform (ZEP), which claim that the maritime CO2 storage sites have no alternative and are safe? For example, the Brussels-based ZEP calls itself the „technical adviser to the EU on the deployment of Carbon Capture and Storage (CCS) and Carbon Capture and Utilisation (CCU)” and describes CCS and CCU as “secure, reliable and sustainable”. ZEP members include BP, Eni, Equinor, ExxonMobil, Shell and Total, i.e., many companies with a major commercial interest in the continued exploitation of fossil fuels.

Over the last decade, the European Union had planned to test the feasibility and economic viability of CCS by intending to establish up to twelve large-scale CCS demonstration projects. However, of these CCS projects, only seven were planned and ultimately none were implemented. The predecessor programme of the European Union Innovation Fund, NER300, aimed to realise one of the planned CCS projects, the “White Rose Plant” adjacent to the Drax Power Station in North Yorkshire, UK. Although this CCS project was funded by the UK government with £ 50 million, it was discontinued in 2015 due to high costs. The European Union has also funded a number of research projects on CCS, including GATEWAY and CEMCAP. GATEWAY describes CCS as a technology that still has “several hurdles to overcome“, e.g., due to its high costs. CEMCAP concludes that:

- “retrofitting existing cement plants with new technologies is not a simple matter”;

- “the core problem is that all CCS processes add 50-90 % to the costs of manufacturing cement”;

- “Without a business case, commercial cement producers are unlikely to adopt CCS voluntarily. The European Commission may have to legislate for compulsory use of the technologies.”

In 2020, researchers at the Geomar Helmholtz Centre for Ocean Research in Kiel, Germany have published a study that found that abandoned oil and gas wells in the North Sea leak considerable amounts of the potent greenhouse gas methane. Of the investigated wells, methane leakage has been detected at 65 % of the wells. In the entire North Sea, more than 20,500 hydrocarbon wells for oil and gas production have been documented. It is alarming that the industrial players that allow methane to escape from their abandoned wells should now be responsible for safely storing CO2. As even the documented wells are not leak-proof and not every hydrocarbon wells are documented – how can it be ensured that the CO2 injected into underground reservoirs does not leak back to the surface from abandoned wells and thus back into the atmosphere? Apart from that, the shifting of the continental plates continues- against this background, how can tectonic changes that could lead to cracks and thus to the escape of CO2 be ruled out in the long term?

The direct air capture market in Europe – high investments and more diversity

Swiss Climeworks AG’s 2022 financing round raised around € 585 millions from private investors. Another main source of revenue for the company is CO2 removal. Since the commissioning of its new direct air capture (DAC) plant in Iceland, Orca, currently the world’s largest DAC plant, new companies have signed contracts with Climeworks for carbon removal, including AMAG Group (April 2022), BCT (Dec. 2021), La Prairie (May 2022), LGT (Dec. 2021), Ocado Retail (Nov. 2021), Rothesay Life (Feb. 2022), Square Inc (Nov. 2021), Swarovski (Mach 2022), Verdane (April 2022), and Zendesk (March 2022). Orca is expected to capture 4,000 tonnes of CO2 annually. The contracts with LGT (9,000 tonnes of CO2 removal), Square Inc (2,000 tonnes of CO2 removal) and Ocado Retail (1,000 tonnes of CO2 removal) alone represent three times Orca’s planned annual capacity. In 2021, Microsoft pre-purchased 1,400 tonnes of CO2 removal from Orca for an undisclosed amount, and Shopify pre-purchased 5,000 tonnes. Currently, the Orca project is behind schedule due to problems with harsh local weather conditions, some of the machines were frozen. Climeworks has not yet given any information on whether the plant can only run on frost-free days or whether it can be retrofitted.

Since June 2019, more than 14,000 private customers have signed up for the purchase of carbon offsets at costs of about € 1,000 per tonne of CO2. If bought in bulk, the cost per tonne of CO2 is lower, e.g., between US$ 600 and US$ 800, depending on the amount of CO2 and the duration of the contract.

According to Climeworks, since September 2021, Climeworks has an annual CO2 removal capacity of about 5,500 tonnes. In addition to Orca, Climeworks also operates a plant in Hinwil, Switzerland, with a capture capacity of 900 tonnes of CO2 per year. However, 600 tonnes of this amount are purchased annually by Coca-Cola Switzerland and used for Coca-Cola brand ‘Valser’ fizzy drinks, i.e., the captured CO2 is released back into the atmosphere as soon as the drinks are consumed. In addition, greenhouse gases are generated by the transport by truck and by the further processing of the CO2.

Whether the 600 tonnes of CO2 are taken into account or not, the amounts seem irrelevant and a tiny fraction, for example, compared to the amount of greenhouse gases emitted into the atmosphere annually in comparatively small Switzerland alone – which was 43.4 million tonnes of CO2 equivalents in 2020, and this amount does not even take into account international air and shipping traffic and emissions generated by imported goods from abroad.

Due to the high demand, Climeworks intends to use the funds from the last financing round to build a DAC plant that can capture 0.04 million tonnes of CO2 per year, which corresponds to ten times the capacity of Orca. Oman, Iceland, Norway and North America have been mentioned as possible locations.

After Climeworks AG has dominated the DAC scene in Europe for many years, the DAC sector in Europe is currently diversifying and changing:

- In April 2022, Carbyon, a Dutch developer of DAC technology, was awarded US$ 1 million in the XPRIZE carbon removal competition funded by Elon Musk and the Musk Foundation.

- In April 2022, the UK-based DAC developer Mission Zero Technologies signed a Memorandum of Understanding with 44.01 for a DAC project in Oman called Project Hajar. The project aims to capture 1,000 tonnes of CO2 annually and won a US$ 1 million prize in Elon Musk’s XPRIZE Carbon Removal competition in April 2022.

- In May 2021, the UK Greenhouse Gas Removal Programme awarded support to develop a cost-effective, membrane-based DAC approach. The DAC project is led by the Dutch company CO2CirculAir BV, a developer of membrane-based DAC technology.

- The German BLANCAIR-to-X project is currently looking for cooperation partners and investors. The BLANCAIR approach combines wind turbines with DAC modules. Up to six DAC modules are housed in a container that is supplied with a continuous flow of air by the rotation of the wind turbine rotors (which create a negative pressure). The ambient air is passed through the DAC modules, which absorb CO2 with amino salts. Heat is required to dissolve the captured CO2 out of the modules. According to the company, the waste heat from the wind generators is sufficient for this. The required energy (electricity, heat) is provided by the wind turbine. In addition, the wind energy can be used to produce H2 through electrolysis. Methane is to be produced from the captured CO2, H2 and electricity. The methane can be fed into the natural gas grid or used to produce synfuel in a refinery.

- Kollsness DAC project: Since November 021, the companies Carbon Removal (Norway), Carbon Engineering (Canada) and Oxy Low Carbon Ventures (subsidiary of Occidental, USA) have been planning a DAC plant in the Norwegian Kollsness area. The plant is expected to capture up to one million tonnes of CO2 per year. The captured CO2 is to be injected underground.

- In February 2022, the Irish Carbon Collect Ltd has raised US$ 12 million in a funding round and installed a first mechanical tree with DAC technology on the Arizona State University campus in Tempe, Arizona, in April 2022.

- Project Dreamcatcher, a joint DAC project announced by Carbon Engineering and Pale Blue Dot Energy in 2020 and considered for the Acorn CCS project at the St. Fergus Gas Plant in Scotland, has been cancelled due to high costs.

- In March 2022, UK-based Storegga and Japan’s Mitsui & Co, Ltd announced joint plans to build a DAC plant in north-east Scotland. The plant is expected to capture one million tonnes of CO2 annually.

- Carbon Neutral Petrol Ltd., a UK-based developer of DAC technology, has dropped out of the UK Greenhouse Gas Removal Programme.

- Since 2021, the Swedish Energy Agency has funded the research project “Negative emissions with Direct Air Capture for Sweden”. The project aims to assess direct air capture (DAC) technology for Swedish conditions, including the entire value chain, technology, economy, business models, and regulatory issues. The project is led by Chalmer University and conducted in collaboration with the Swedish research institute RISE and Nordic DAC Group AB. The Nordic DAC Group aims to establish DAC plants in Sweden based on DAC technology developed by Carbon Engineering Ltd (Canada).

- Selection of other active DAC companies and projects in Europe: Carbominer (Ukraine), Hydrocell Oy (Finland), Project ENCORE (Rolls-Royce and CSIRO, UK), Sizewell C (UK), Skytree (the Netherlands), SolarFoods (Finland), Soletair Oy (Finland),

Even though the DAC sector has undergone changes, DAC research still centres around the same problems – high costs and excessively high energy consumption, thereby adding emissions to the atmosphere rather than removing CO2 over the entire life cycle.