Carbon Capture and Storage

Type

Areas of deployment

Proposal

Featured project

Show on map

Latest technology update

Show update

Description and purpose of the technology

Carbon Capture and Storage (CCS) technology was originally developed by the oil industry to recover difficult-to-access deep oil reserves, and was used for Enhanced Oil Recovery (EOR). EOR involves pumping pressurized carbon dioxide into oil reservoirs to extract otherwise inaccessible remaining deposits from aging oil fields, which significantly boosts production. Using CCS for EOR has been in use for more than 45 years, particularly in the United States, but it hasn’t been used extensively because of high costs.

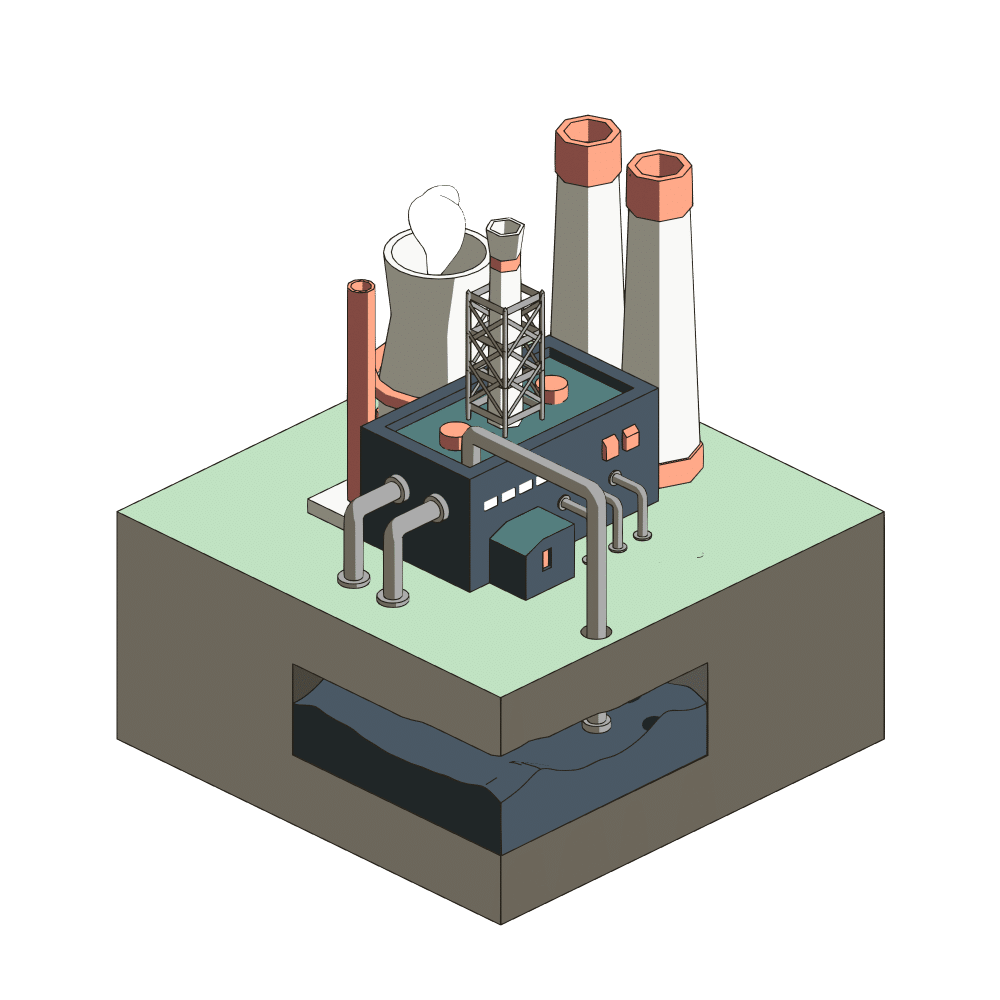

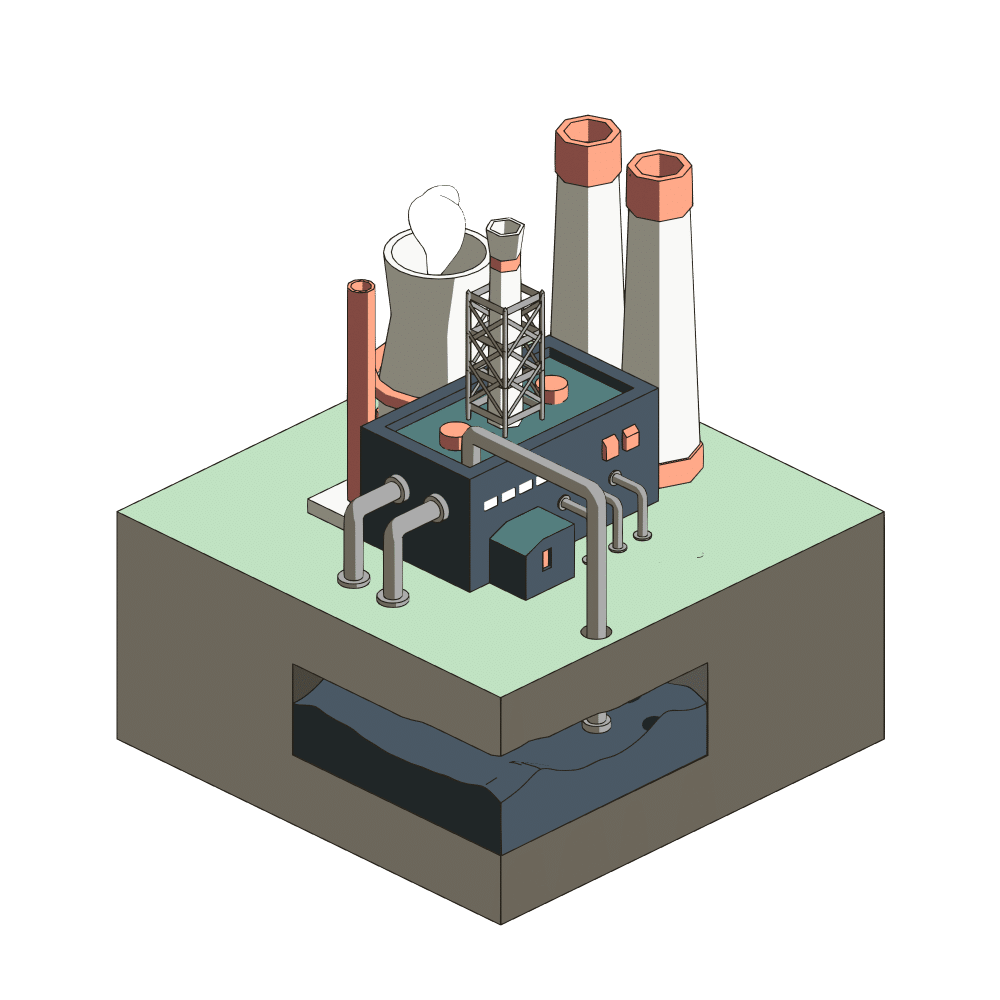

Whilst still strongly linked to EOR, CCS is now described as a Carbon Dioxide Removal (CDR) strategy and has wider applications. It aims to capture and bury carbon dioxide emitted through fossil-fuel combustion, cement and steel production, hydrocarbon refining and some other industrial processes. The captured carbon dioxide is compressed into a liquid form and transported by pipeline to a site where it can be pumped underground into geological formations, such as oil or gas reservoirs, saline aquifers or below the seabed, theoretically for long-term storage.

Carbon dioxide is most commonly removed from exhaust gasses post-combustion, and all carbon capture approaches involve using a substance to act as a selective carbon dioxide filter that the carbon dioxide dissolves in or sticks to. The most frequently used substances are liquid solvents, and other filters include solid sorbents and membranes.

In order to allow their repetitive use, the filters must be able to release the captured carbon dioxide. This regeneration process typically requires high temperatures, which in turn require high energy inputs, referred to as an energy penalty that reduces the efficiency of the facility where carbon is being captured. In order to power the CCS process, the consumption of fossil fuels typically increases by up to 40%, making it a costly process energetically and financially. The capture process is the most energy-intensive, resulting in an increase of up to 30%. This means that for a coal-fired power station with CCS, even more coal would need to be mined and burned in order to produce the same amount of energy as a plant without CCS. [1]

The International Energy Agency’s (IEA) CCS Unit now describes “Advanced EOR+” as a way to “‘co-exploit’ two business activities”: oil recovery and carbon dioxide storage for profit. [2] Although CCS leads to the extraction and combustion of more fossil fuels, carries significant environmental risks, such as carbon dioxide escaping through leaks, is costly and technologically challenging, it is presented as a “climate technology” as a means of capturing climate finance. The capture and gas compression phases in particular account for as much as 90% of the total financial cost of CCS. [3]

Actors involved

Oil companies are particularly interested in developing CCS because it provides a source of subsidized carbon dioxide for EOR and allows them to extract more oil. Decades of research and billions spent by governments and companies, such as Shell, Statoil and ExxonMobil have resulted in only a few commercial-scale CCS operations, highlighting the extent to which CCS is only commercially viable when used for EOR. Of the 21 operational, commercial-scale CCS facilities world-wide listed by the Global CCS Institute in 2021, the captured carbon dioxide was used for EOR in 16 of them, and the two facilities listed as being under construction were also linked to EOR. [4] In North America, carbon captured from the only large-scale CCS-equipped power plants—Petra Nova in Texas, and SaskPower in Saskatchewan (both coal-fired)—is transported via pipeline to oil fields for EOR.

This clearly shows that the motivation for CCS is further oil production, which will increase emissions. The United States Department of Energy, the largest public funder of CCS projects, claims that an additional 200 billion barrels of oil could be recovered in the United States by utilizing carbon dioxide for EOR, doubling the amount of recoverable oil reserves. [5]

Governments and the fossil fuel industry have for many years presented CCS as a silver bullet for climate change, with the promise of the technology being a consistent excuse for delaying serious reductions in fossil fuel consumption.

Impacts of the technology

The main impact of CCS is that it extends the life of fossil fuel infrastructure and provides an excuse for continued fossil fuel extraction, and the symbiotic relationship between CCS and EOR undermines its theoretical potential as a climate change mitigation tool. Beyond the extra emissions associated with the recovered oil, oil industry estimates indicate that about 30% of the carbon dioxide piped to an EOR site will be emitted back into the atmosphere. [6]

CCS (and Bioenergy with CCS, see BECCS Technology Briefing) proponents claim that storing carbon dioxide in old oil and gas reservoirs, deep saline aquifers or below the seabed is effective and reliable. However, real-world experience suggests otherwise—the carbon dioxide could leak out of injection sites for many reasons, including faulty construction, earthquakes or other underground movements. Whether small amounts over a long time, or an abrupt, potentially catastrophic release, leakage would undermine any storage gains. Even meticulous preparation cannot prevent leaks, and there are also a lack of reliable and accurate methods of identifying and measuring leaks across injection sites. At such high concentrations, carbon dioxide leaks are highly toxic to animal and plant life. Injected carbon dioxide can also displace pollutants and saline groundwater, which could lead to the contamination of surface freshwater sources. At offshore sites, CCS may also increase ocean acidification and adversely affect marine ecosystems. [7]

The following examples highlight the uncertainties of underground carbon dioxide storage:

- In 2000, Cenovus Energy began injecting carbon dioxide into the Weyburn oil field in Canada from a coal gasification plant. [8] Residents became concerned after unexplained farm animal deaths and observations of bubbling and an oily film on their ponds. Years later, the true scale of leakages at Weyburn are still not known, with published studies claiming to both prove and disprove that leakages occurred. [9]

- The Sleipner project in the North Sea, operated by ExxonMobil, Statoil, Lotos Norge and Total, has been injecting up to one million tonnes of carbon dioxide a year into a sub-seabed saline aquifer, captured from a natural gas processing facility. Observations have been reported of oily water, an oil leak, unexplained cracking and damage to rock layers and unanticipated movements of injected carbon dioxide through the formation. These observations are coupled with a significant discrepancy between the amount of carbon dioxide injected and what has been detected in seismic surveys. [10]

- A joint venture between BP and Statoil in Algeria injected carbon dioxide captured from a gas production site into three wells between 2004 and 2011. A seismic study indicated that injection had activated a deep fracture zone, [11] and leakage was found from a nearby well head. [12]

- In the USA, over three million old oil and gas wells have been abandoned and remain unplugged, [13] and many of them penetrate into the deeper formations currently being used or considered for CCS. [14] These old wells represent a huge number of potential leakage pathways.

- Plans for onshore carbon dioxide storage, particularly in Europe, have been met with strong protests over safety concerns, leading to a number of projects being cancelled. [15]

Reality check

CCS is largely aspirational, extremely expensive and there is little evidence that it is effective. It is mainly of interest to oil producing countries and the oil industry as a means of attracting subsidies and avoiding production cuts. High costs and technical issues have led to a wave of high-profile project cancellations in recent years; the suspension of the Petra Nova CCS project in Texas in 2020 (which recommenced in 2023) is among the most recent examples. Even projects that have managed to become operational and have been heralded as successful have been plagued with problems. [16] The fact that several CDR technologies rely on CCS, such as Bioenergy with CCS and Direct Air Capture, should also be a serious cause for concern.

Further reading

CIEL (2019), Fuel to the Fire: How Geoengineering Threatens to Entrench Fossil Fuels and Accelerate the Climate Crisis, https://www.ciel.org/reports/fuel-to-the-fire-how-geoengineering-threatens-to-entrench-fossil-fuels-and-accelerate-the-climate-crisis-feb-2019/

Geoengineering Monitor (2020), Carbon capture is the fossil fuel giants’ plant to keep extracting, https://www.geoengineeringmonitor.org/2020/03/carbon-capture-is-the-fossil-fuel-giants-plan-to-keep-extracting/

Greenpeace (2015), Carbon Capture SCAM, http://www.greenpeace.org/usa/research/carbon-capture-scam/

Biofuelwatch, BECCS: Last ditch climate option or wishful thinking?, http://www.biofuelwatch.org.uk/2015/beccs-report/

ETC Group and Heinrich Böll Foundation, Geoengineering Map, https://map.geoengineeringmonitor.org/

End notes

[1] ETC Group and Heinrich Böll Foundation (2020) Geoengineering Map, https://map.geoengineeringmonitor.org/ ; German Federal Environmental Agency (2018) Carbon Capture and Storage, published online: April 18, 2018, https://www.umweltbundesamt.de/themen/wasser/gewaesser/grundwasser/nutzung-belastungen/carbon-capture-storage#grundlegende-informationen;

House, et al. (2009) The energy penalty of post-combustion CO2 capture & storage and its implications for retrofitting the U.S. installed base, in Energy & Environmental Science, Issue 2, https://pubs.rsc.org/en/content/articlelanding/2009/ee/b811608c#!divAbstract

[2] Heidug, et al. (2015) Storing CO2 through Enhanced Oil Recovery: Combining EOR with CO2 storage (EOR+) for profit, International Energy Agency, Insights Series 2015, p.6, https://nachhaltigwirtschaften.at/resources/iea_pdf/reports/iea_ghg_storing_co2_trough_enhanced_oil_recovery.pdf

[3] Folger (2017) Carbon Capture and Sequestration (CCS) in the United States, Congressional Research Service, published: November 14, 2017, p. 12, https://www.ourenergypolicy.org/wp-content/uploads/2017/11/R44902-1.pdf; House, et al. (2009); German Federal Environmental Agency (2018)

[4] Global CCS Institute (2019) Global Status Of CCS 2019, https://www.globalccsinstitute.com/wp-content/uploads/2019/12/GCC_GLOBAL_STATUS_REPORT_2019.pdf; Global CCS Institute (2020) Global CCS Institute welcomes the 20th and 21st large-scale CCS facilities into operation, published: June 3, 2020, https://www.globalccsinstitute.com/news-media/press-room/media-releases/global-ccs-institute-welcomes-the-20th-and-21st-large-scale-ccs-facilities-into-operation/

[5] National Energy Technology Laboratory (2020) Commercial Carbon Dioxide Uses: Carbon Dioxide Enhanced Oil Recovery, US-DOE, accessed: June 2020, https://netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/eor;

ETC Group and Heinrich Böll Foundation (2020)

[6] Ernsting and Munnion (2015), Last ditch climate option of wishful thinking? Bioenergy with carbon capture and storage, Biofuelwatch, http://www.biofuelwatch.org.uk/2015/beccs-report/

[7] Gross, et al. (2019) Simulating and Quantifying Multiple Natural Subsea CO2 Seeps at Panarea Island (Aeolian Islands, Italy) as a Proxy for Potential Leakage from Subseabed Carbon Storage Sites, in Environ. Sci. Technol., Vol. 53(17): 10258 – 10268, https://pubs.acs.org/doi/abs/10.1021/acs.est.9b02131; German Federal Environmental Agency (2018); Skuce (2016) ‘We’d have to finish one new facility every working day for the next 70 years’—Why carbon capture is no panacea, in: Bulletin of the Atomic Scientists, published: October 4, 2016, https://thebulletin.org/2016/10/wed-have-to-finish-one-new-facility-every-working-day-for-the-next-70-years-why-carbon-capture-is-no-panacea/

[8] Whittaker, et al. (2011) A decade of CO2 injection into depleting oil fields: Monitoring and research activities of the IEA GHG Weyburn-Midale CO2 Monitoring and Storage Project,” in Energy Procedia, Vol. 4: 6069 – 6076, https://www.sciencedirect.com/science/article/pii/S1876610211008915

[9] Ernsting and Munnion (2015)

[10] Ernsting and Munnion (2015)

[11] Stork, et al. (2015) The microseismic response at the In Salah Carbon Capture and Storage (CCS) site, in: International Journal of Greenhouse Gas Control, Vol. 32: 159 – 171, https://doi.org/10.1016/j.ijggc.2014.11.014

[12] Wright, et al. (2010) In Salah CO2 Storage JIP: Site Selection, Management, Field Development Plan and Monitoring Overview, in: Energy Procedia: 614 – 1000

[13] Gale (2014) IEAGHG Information Paper 2014-27; The Trouble with Abandoned Wells, IEA Greenhouse Gas R&D Programme, December 23, 2014; Weingarten, et al. (2015) High-rate injection is associated with the increase in U.S. mid-continent seismicity, in Science, Vol. 348(6241): 1336 – 1340, https://science.sciencemag.org/content/348/6241/1336

[14] Ide, et al. (2006) CO2 leakage through existing wells: current technology and regulations, in: Proceedings of the 8th International Conference on Greenhouse Gas Control Technologies, International Energy Agency Greenhouse Gas Programme: Elsevier, Netherlands (2006)

[15] Neslen (2015) Europe’s carbon capture dream beset by delays, fears and doubt, in: The Guardian, published: April 9, 2015, https://www.theguardian.com/environment/2015/apr/09/carbon-capture-dream-norway-beset-by-delays-fears-doubt-europe

[16] Greenpeace (2016) Carbon capture and storage a costly, risky distraction, published: July 1, 2016, http://www.greenpeace.org/international/en/campaigns/climate-change/Solutions/Reject-false-solutions/Reject-carbon-capture–storage/; Anchondo and Klump (2020) Petra Nova is closed: What it means for carbon capture, in: E&E News, September 22, 2020, https://www.eenews.net/stories/1063714297; ETC Group and Heinrich Böll Foundation (2020)

Carbon Capture and Storage

TIPO

Zonas de despliegue

Propuesta

Proyecto destacado

Mostrar en el mapa

Última actualización de la tecnología

Mostrar actualización

Descripción y propósito de la tecnología

Carbon Capture and Storage (CCS) technology was originally developed by the oil industry to recover difficult-to-access deep oil reserves, and was used for Enhanced Oil Recovery (EOR). EOR involves pumping pressurized carbon dioxide into oil reservoirs to extract otherwise inaccessible remaining deposits from aging oil fields, which significantly boosts production. Using CCS for EOR has been in use for more than 45 years, particularly in the United States, but it hasn’t been used extensively because of high costs.

Whilst still strongly linked to EOR, CCS is now described as a Carbon Dioxide Removal (CDR) strategy and has wider applications. It aims to capture and bury carbon dioxide emitted through fossil-fuel combustion, cement and steel production, hydrocarbon refining and some other industrial processes. The captured carbon dioxide is compressed into a liquid form and transported by pipeline to a site where it can be pumped underground into geological formations, such as oil or gas reservoirs, saline aquifers or below the seabed, theoretically for long-term storage.

Carbon dioxide is most commonly removed from exhaust gasses post-combustion, and all carbon capture approaches involve using a substance to act as a selective carbon dioxide filter that the carbon dioxide dissolves in or sticks to. The most frequently used substances are liquid solvents, and other filters include solid sorbents and membranes.

In order to allow their repetitive use, the filters must be able to release the captured carbon dioxide. This regeneration process typically requires high temperatures, which in turn require high energy inputs, referred to as an energy penalty that reduces the efficiency of the facility where carbon is being captured. In order to power the CCS process, the consumption of fossil fuels typically increases by up to 40%, making it a costly process energetically and financially. The capture process is the most energy-intensive, resulting in an increase of up to 30%. This means that for a coal-fired power station with CCS, even more coal would need to be mined and burned in order to produce the same amount of energy as a plant without CCS. [1]

The International Energy Agency’s (IEA) CCS Unit now describes “Advanced EOR+” as a way to “‘co-exploit’ two business activities”: oil recovery and carbon dioxide storage for profit. [2] Although CCS leads to the extraction and combustion of more fossil fuels, carries significant environmental risks, such as carbon dioxide escaping through leaks, is costly and technologically challenging, it is presented as a “climate technology” as a means of capturing climate finance. The capture and gas compression phases in particular account for as much as 90% of the total financial cost of CCS. [3]

Actores involucrados

Oil companies are particularly interested in developing CCS because it provides a source of subsidized carbon dioxide for EOR and allows them to extract more oil. Decades of research and billions spent by governments and companies, such as Shell, Statoil and ExxonMobil have resulted in only a few commercial-scale CCS operations, highlighting the extent to which CCS is only commercially viable when used for EOR. Of the 21 operational, commercial-scale CCS facilities world-wide listed by the Global CCS Institute in 2021, the captured carbon dioxide was used for EOR in 16 of them, and the two facilities listed as being under construction were also linked to EOR. [4] In North America, carbon captured from the only large-scale CCS-equipped power plants—Petra Nova in Texas, and SaskPower in Saskatchewan (both coal-fired)—is transported via pipeline to oil fields for EOR.

This clearly shows that the motivation for CCS is further oil production, which will increase emissions. The United States Department of Energy, the largest public funder of CCS projects, claims that an additional 200 billion barrels of oil could be recovered in the United States by utilizing carbon dioxide for EOR, doubling the amount of recoverable oil reserves. [5]

Governments and the fossil fuel industry have for many years presented CCS as a silver bullet for climate change, with the promise of the technology being a consistent excuse for delaying serious reductions in fossil fuel consumption.

Impactos de la tecnología

The main impact of CCS is that it extends the life of fossil fuel infrastructure and provides an excuse for continued fossil fuel extraction, and the symbiotic relationship between CCS and EOR undermines its theoretical potential as a climate change mitigation tool. Beyond the extra emissions associated with the recovered oil, oil industry estimates indicate that about 30% of the carbon dioxide piped to an EOR site will be emitted back into the atmosphere. [6]

CCS (and Bioenergy with CCS, see BECCS Technology Briefing) proponents claim that storing carbon dioxide in old oil and gas reservoirs, deep saline aquifers or below the seabed is effective and reliable. However, real-world experience suggests otherwise—the carbon dioxide could leak out of injection sites for many reasons, including faulty construction, earthquakes or other underground movements. Whether small amounts over a long time, or an abrupt, potentially catastrophic release, leakage would undermine any storage gains. Even meticulous preparation cannot prevent leaks, and there are also a lack of reliable and accurate methods of identifying and measuring leaks across injection sites. At such high concentrations, carbon dioxide leaks are highly toxic to animal and plant life. Injected carbon dioxide can also displace pollutants and saline groundwater, which could lead to the contamination of surface freshwater sources. At offshore sites, CCS may also increase ocean acidification and adversely affect marine ecosystems. [7]

The following examples highlight the uncertainties of underground carbon dioxide storage:

- In 2000, Cenovus Energy began injecting carbon dioxide into the Weyburn oil field in Canada from a coal gasification plant. [8] Residents became concerned after unexplained farm animal deaths and observations of bubbling and an oily film on their ponds. Years later, the true scale of leakages at Weyburn are still not known, with published studies claiming to both prove and disprove that leakages occurred. [9]

- The Sleipner project in the North Sea, operated by ExxonMobil, Statoil, Lotos Norge and Total, has been injecting up to one million tonnes of carbon dioxide a year into a sub-seabed saline aquifer, captured from a natural gas processing facility. Observations have been reported of oily water, an oil leak, unexplained cracking and damage to rock layers and unanticipated movements of injected carbon dioxide through the formation. These observations are coupled with a significant discrepancy between the amount of carbon dioxide injected and what has been detected in seismic surveys. [10]

- A joint venture between BP and Statoil in Algeria injected carbon dioxide captured from a gas production site into three wells between 2004 and 2011. A seismic study indicated that injection had activated a deep fracture zone, [11] and leakage was found from a nearby well head. [12]

- In the USA, over three million old oil and gas wells have been abandoned and remain unplugged, [13] and many of them penetrate into the deeper formations currently being used or considered for CCS. [14] These old wells represent a huge number of potential leakage pathways.

- Plans for onshore carbon dioxide storage, particularly in Europe, have been met with strong protests over safety concerns, leading to a number of projects being cancelled. [15]

Visión realista

CCS is largely aspirational, extremely expensive and there is little evidence that it is effective. It is mainly of interest to oil producing countries and the oil industry as a means of attracting subsidies and avoiding production cuts. High costs and technical issues have led to a wave of high-profile project cancellations in recent years; the suspension of the Petra Nova CCS project in Texas in 2020 (which recommenced in 2023) is among the most recent examples. Even projects that have managed to become operational and have been heralded as successful have been plagued with problems. [16] The fact that several CDR technologies rely on CCS, such as Bioenergy with CCS and Direct Air Capture, should also be a serious cause for concern.

Lectura complementaria

CIEL (2019), Fuel to the Fire: How Geoengineering Threatens to Entrench Fossil Fuels and Accelerate the Climate Crisis, https://www.ciel.org/reports/fuel-to-the-fire-how-geoengineering-threatens-to-entrench-fossil-fuels-and-accelerate-the-climate-crisis-feb-2019/

Geoengineering Monitor (2020), Carbon capture is the fossil fuel giants’ plant to keep extracting, https://www.geoengineeringmonitor.org/2020/03/carbon-capture-is-the-fossil-fuel-giants-plan-to-keep-extracting/

Greenpeace (2015), Carbon Capture SCAM, http://www.greenpeace.org/usa/research/carbon-capture-scam/

Biofuelwatch, BECCS: Last ditch climate option or wishful thinking?, http://www.biofuelwatch.org.uk/2015/beccs-report/

ETC Group and Heinrich Böll Foundation, Geoengineering Map, https://map.geoengineeringmonitor.org/

Notas finales

[1] ETC Group and Heinrich Böll Foundation (2020) Geoengineering Map, https://map.geoengineeringmonitor.org/ ; German Federal Environmental Agency (2018) Carbon Capture and Storage, published online: April 18, 2018, https://www.umweltbundesamt.de/themen/wasser/gewaesser/grundwasser/nutzung-belastungen/carbon-capture-storage#grundlegende-informationen;

House, et al. (2009) The energy penalty of post-combustion CO2 capture & storage and its implications for retrofitting the U.S. installed base, in Energy & Environmental Science, Issue 2, https://pubs.rsc.org/en/content/articlelanding/2009/ee/b811608c#!divAbstract

[2] Heidug, et al. (2015) Storing CO2 through Enhanced Oil Recovery: Combining EOR with CO2 storage (EOR+) for profit, International Energy Agency, Insights Series 2015, p.6, https://nachhaltigwirtschaften.at/resources/iea_pdf/reports/iea_ghg_storing_co2_trough_enhanced_oil_recovery.pdf

[3] Folger (2017) Carbon Capture and Sequestration (CCS) in the United States, Congressional Research Service, published: November 14, 2017, p. 12, https://www.ourenergypolicy.org/wp-content/uploads/2017/11/R44902-1.pdf; House, et al. (2009); German Federal Environmental Agency (2018)

[4] Global CCS Institute (2019) Global Status Of CCS 2019, https://www.globalccsinstitute.com/wp-content/uploads/2019/12/GCC_GLOBAL_STATUS_REPORT_2019.pdf; Global CCS Institute (2020) Global CCS Institute welcomes the 20th and 21st large-scale CCS facilities into operation, published: June 3, 2020, https://www.globalccsinstitute.com/news-media/press-room/media-releases/global-ccs-institute-welcomes-the-20th-and-21st-large-scale-ccs-facilities-into-operation/

[5] National Energy Technology Laboratory (2020) Commercial Carbon Dioxide Uses: Carbon Dioxide Enhanced Oil Recovery, US-DOE, accessed: June 2020, https://netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/eor;

ETC Group and Heinrich Böll Foundation (2020)

[6] Ernsting and Munnion (2015), Last ditch climate option of wishful thinking? Bioenergy with carbon capture and storage, Biofuelwatch, http://www.biofuelwatch.org.uk/2015/beccs-report/

[7] Gross, et al. (2019) Simulating and Quantifying Multiple Natural Subsea CO2 Seeps at Panarea Island (Aeolian Islands, Italy) as a Proxy for Potential Leakage from Subseabed Carbon Storage Sites, in Environ. Sci. Technol., Vol. 53(17): 10258 – 10268, https://pubs.acs.org/doi/abs/10.1021/acs.est.9b02131; German Federal Environmental Agency (2018); Skuce (2016) ‘We’d have to finish one new facility every working day for the next 70 years’—Why carbon capture is no panacea, in: Bulletin of the Atomic Scientists, published: October 4, 2016, https://thebulletin.org/2016/10/wed-have-to-finish-one-new-facility-every-working-day-for-the-next-70-years-why-carbon-capture-is-no-panacea/

[8] Whittaker, et al. (2011) A decade of CO2 injection into depleting oil fields: Monitoring and research activities of the IEA GHG Weyburn-Midale CO2 Monitoring and Storage Project,” in Energy Procedia, Vol. 4: 6069 – 6076, https://www.sciencedirect.com/science/article/pii/S1876610211008915

[9] Ernsting and Munnion (2015)

[10] Ernsting and Munnion (2015)

[11] Stork, et al. (2015) The microseismic response at the In Salah Carbon Capture and Storage (CCS) site, in: International Journal of Greenhouse Gas Control, Vol. 32: 159 – 171, https://doi.org/10.1016/j.ijggc.2014.11.014

[12] Wright, et al. (2010) In Salah CO2 Storage JIP: Site Selection, Management, Field Development Plan and Monitoring Overview, in: Energy Procedia: 614 – 1000

[13] Gale (2014) IEAGHG Information Paper 2014-27; The Trouble with Abandoned Wells, IEA Greenhouse Gas R&D Programme, December 23, 2014; Weingarten, et al. (2015) High-rate injection is associated with the increase in U.S. mid-continent seismicity, in Science, Vol. 348(6241): 1336 – 1340, https://science.sciencemag.org/content/348/6241/1336

[14] Ide, et al. (2006) CO2 leakage through existing wells: current technology and regulations, in: Proceedings of the 8th International Conference on Greenhouse Gas Control Technologies, International Energy Agency Greenhouse Gas Programme: Elsevier, Netherlands (2006)

[15] Neslen (2015) Europe’s carbon capture dream beset by delays, fears and doubt, in: The Guardian, published: April 9, 2015, https://www.theguardian.com/environment/2015/apr/09/carbon-capture-dream-norway-beset-by-delays-fears-doubt-europe

[16] Greenpeace (2016) Carbon capture and storage a costly, risky distraction, published: July 1, 2016, http://www.greenpeace.org/international/en/campaigns/climate-change/Solutions/Reject-false-solutions/Reject-carbon-capture–storage/; Anchondo and Klump (2020) Petra Nova is closed: What it means for carbon capture, in: E&E News, September 22, 2020, https://www.eenews.net/stories/1063714297; ETC Group and Heinrich Böll Foundation (2020)